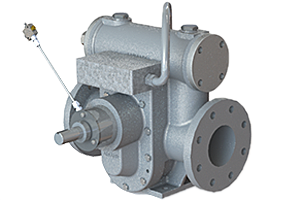

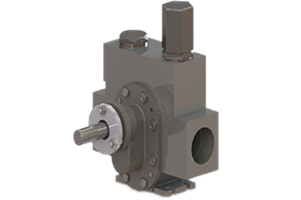

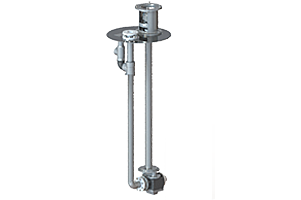

GB – Heated and unheated pumps

The new AP & HD versions

Summary:

The GB range is a heated gear pump primarily designed for pumping products that have to be heated to be pumped. The design can incorporate heating by thermostatically controlled electric heaters (230 volt or 110 volt), thermal oil or steam. Heated gear pumps are typically used for Bitumen, Crude Oil or Refined Tar among other generally viscous fluids. Our pumps are often supplied with a grease filled seal cartridge to give the best possible service life. The seal cartridge can be supplied with a greaser which can be mounted remotely to allow easy greasing of the seal cartridge. This arrangement avoids the leakage so often associated with bitumen pumps.Suited to:

Often virtually maintenance free, GB pumps are perfect for market sectors that require long service lives from heated pumps.Features:

- Highly customisable range of gear pumps, with heating capabilities by steam, electric heaters or thermal oil

- Versions available without heating if required

- A simple, two moving part design

- Internal bearings which cater for self lubricating liquids, with external lubrication also available to those who require it

- Discharge pressure of up to 12 bar (175 psi)

- Supplied with or without an integral relief valve

- Can heat and operate with fluids at up to 220 °C

- Capacity: up to 1600 litres per minute

- A choice of rotors available - straight spur gears, double helical gears

- Double helical gears give almost pulse free operation

Applications:

Our Heated Pumps are suited to pumping a range of liquids, especially thick high viscosity, such as:

to pumping a range of liquids, especially thick high viscosity, such as:

- Refined tar

- Bitumen

- Asphalt

- Cocoa butter

- Wax

- Molasses

- Fats

- Soap

- Cocoa mass

- Paints

- Glue

- Grease

- Resins

- Varnish

- Glucose

- Viscose

- Silicate of soda

- Oils

- Chocolate

- Printing ink

- Cocoa liquor

- Alkalis

- Polymers

- Foodstuffs

Technical talk:

Our GB pumps have a range of options which we can specify with you to ensure that your gear pump is ideal for your application.

- Cast iron: usually used for pumps up to 200 degrees celsius. At even higher temperatures, cast steel is used

- All pumps have hardened steel shafts

- Pump inlet and outlet: connections available to suit individual requirements, however DIN PN16 is standard

- Relief valves: can be fitted to standard pumps

- High temp: special high temperature bearing material is used to ensure long life

- Gland packing: selected to suit individual application

- Albany seal cartridge: can be used as an alternative to packed

- Electric heating: can be 110 volt or 230 volt. Up to 1200 watts is available to keep the pump at 120 degrees celsius with a thermostat

Related Case Study

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in