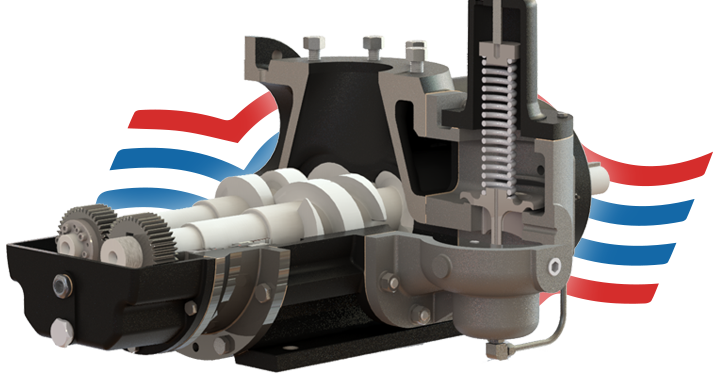

Twin Screw Pumps

Now known as the 'S' range in our updated selection of pumps, Albany Pumps has been making these high speed, quiet-running screw pumps for over 20 years. Our clients in the oil and marine markets have found that Twin Screw Pumps best meet their needs, as they are capable of handling the wide range of viscosities that are often encountered with hydrocarbon liquids - as well as efficiently pumping them at a range of temperatures. Having owned the rights to the successful Stothert & Pitt brand since early 2000, we have significant experience and over the years we have also developed the design to create our own range of cost-effective and modern Albany Twin Screw Pumps. We do also have triple screw pumps currently under research.

Why choose a Twin Screw Pump?

Twin screw pumps give pulse free smooth flow. They have good gas handling characteristics, which is why they are often used for line stripping duties running alongside much larger pumps in refineries or ship loading. The use of external timing gears ensures that the screws do not touch. Albany manufacture screw pumps in different versions where the timing gears are lubricated by the pumped fluid, or separated to allow the pumping of corrosive or other more difficult fluids.Benefits:

These compact pumps are not only quiet in operation, but can also be specified to have great gas handling characteristics. Moreover, our Twin Screw Pumps are hydraulically balanced, allowing for optimum efficiency when pumping oil, fresh sea water and fire foam. With these basic principles in mind, our twin screw pumps can be customised to fit our cusomers' requirements, creating a truly bespoke service. We manufacture Twin Screw Pumps for many applications and processes, including but not limited to pumping:- Crude oil

- Fuel oil

- Aviation fuel

- Bitumen

- Asphalt

- Fresh sea water

- Oily water/slops

- Flare scrubbing

- Fire foam injection

- Line stripping

- Cargo pumping

- Has a capacity of up to 1000m³/hr

- Pressures go up to generally 25 bar, some to 50 bar

- Pumps are available with either internal or external bearing configurations

- Steam heating/water cooling jackets if required

- Horizontal or vertical mounting

- Smooth operation with low resonance and noise levels

- Flange sizes up to 8"