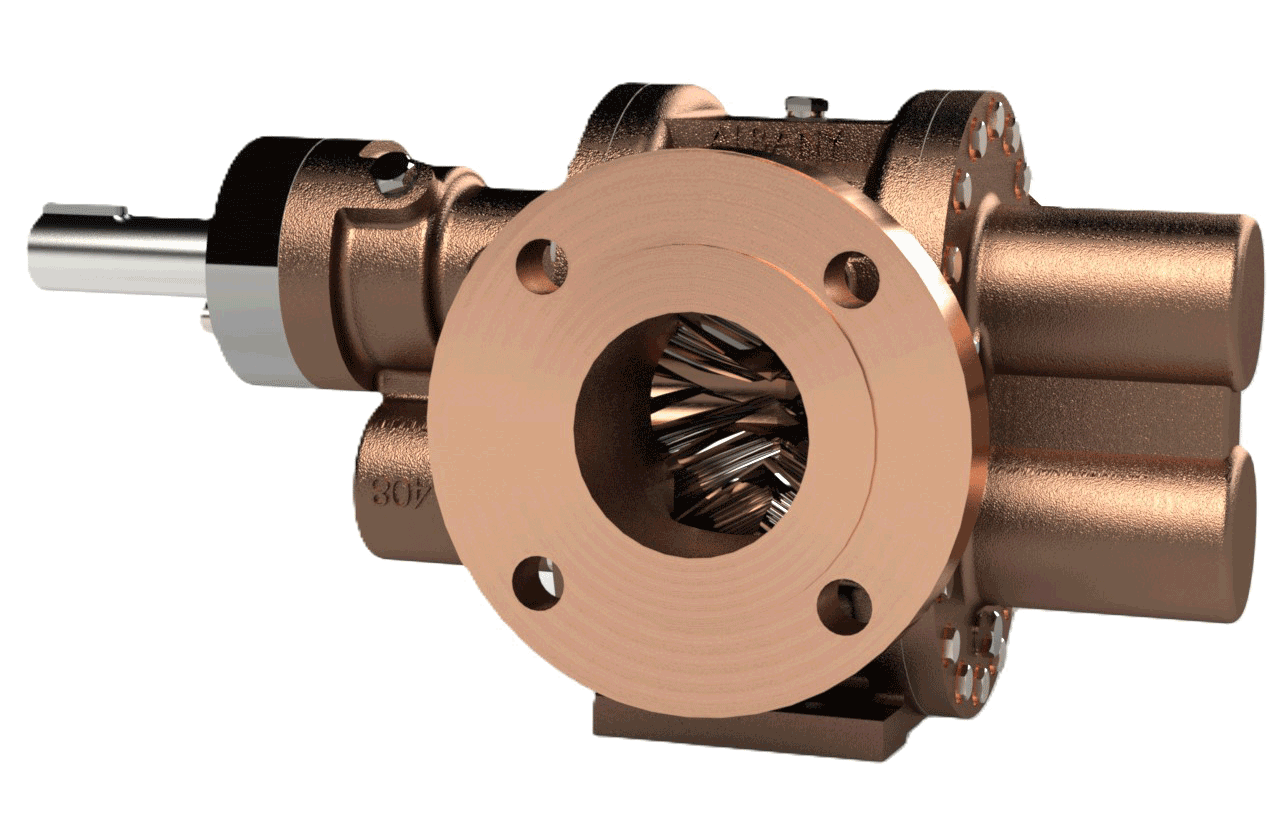

CA – Centrifugal pumps (customised)

Our C range of Centrifugal Pumps can be supplied as new pumps or as replacements in a variety of differing materials. Albany Pumps manufacture our own supply of long-established designs, first created by Stothert and Pitt. We manufacture Centrifugal Pumps to accommodate the heavy-duty requirements of applications, including foods and other types of cargo. Available in either horizontal or vertical mounted options with a bearing bracket, these pumps can be easily removed for maintenance without disturbing driver, suction or delivery pipework.

Why choose an Centrifugal Pump?

Our range of column centrifugal pumps is ideal for a variety of situations. Most widely used in the General and Chemical, Fire, Lubrication, Marine and Oil & Gas industries, these pumps can be customised to fit your specific pumping needs. Centrifugal Pumps can handle a range of temperatures up to 180 °C and can be manufactured in either cast iron, steel or stainless steel, with a range of added extra options for user convenience.Benefits:

Albany's Centrifugal Pumps use the kinetic energy of the motor to move the liquid cargo through the axis - reminiscent of a water wheel style. The rotation creates a flow which moves the water from its entry point through the casing of the pump to the discharge end. Centrifugal Pumps are very useful when applied to sewage, petroleum and chemical pumping because of their compact design and minimal maintenance requirements. The output of these pumps is very consistent and steady, allowing for a high speed. Albany manufacture Centrifugal Pumps for:- Aviation fuels

- Hot oil on commercial cooking ranges

- Hot oil in quenching plants

- Salty formation water

- Slop oil

- Fresh water

- Seawater

- Low viscosity petroleum products

Features:

- Capacity of up to 300m³/hr

- Can handle pressures of up to 200 psi

- Horizontal or vertical mounted unit

- Close-coupled or spacer-coupled

- Non-self priming or vane type primers as required

- Run at 2 or 4 pole electric motor speeds - 50Hz or 60Hz

- 6 or 8 pole speeds can also be used where desired

- Manufactured in cast iron, steel or stainless steel