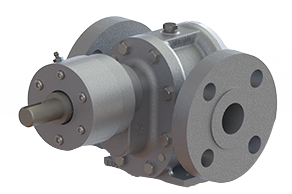

GC – Compressor/turbine pumps

Summary:

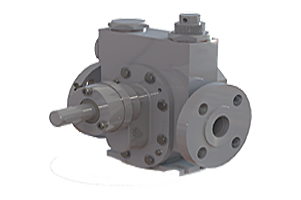

The GC range refers to compressor and turbine pumps, specifically designed to be used by OEMs in those industries. Fully capable, with a high system pressure layout, these C style pumps offer extra rigidity around the drive shaft and particular internal options. All of our pumps can be customised to include parts that help the customer's process or aid fitting into an existing framework, mountings and pipework. Specialised paint finishes can also be catered for. All these options, and more, can be discussed with our knowledgeable team upon specification. Radial and axial location bearing options are provided as well as vertical and horizontal formats. NOTE: For API certified pump requirements, use the GG range pumps.Suited to:

A sturdy range of double bearing pumps, these solutions are primarily used for the Oil & Gas industries with their stringent requirements, but we also find our customers from the Refrigeration and also Lubrication markets working well with the GC range.Features:

- Specialised paint finishes can be catered for

- Up to 3,000 cSt viscosity at 500 rpm

- Pumps can be coupled to an electric motor. Pumps are often directly driven off a compressor or turbine via a gearbox or other power take off.

- The GC gear pump range are available with jacketed bodies or covers.

Applications:

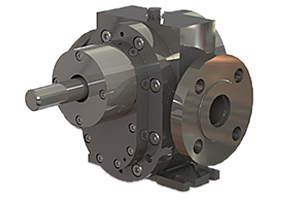

Our GC pump range is normally used for pumping lubricating oil in gas turbines or air compressors. A wide range of other fluids could be pumped by this type of pump if required.

Technical talk:

Covering a variety of specifications, these compressor and turbine pumps have many additional optionsto choose from which will allow you to create the most suitable pump for your desired use:

- Bearings: Remote ball and roller bearings can be supplied where nature of fluid overrules internal bearings use

- Sealing: Can be fitted with mechanical seals or packed glands where required

- Viscous liquids: GC punps can be supplied for a range of viscosities with structured pipe work on the suction side

- High pressure: For high pressure requirements, our pumps use large size plain bearings, providing hydrodynamic operation at all viscosities

- Relief valves: Will give a ‘full bore’ relief on all but the highest viscosity liquids. Adjustable per pressure and direction of rotation

- Corrosion resistant: Can be offered in stainless steel, bronze, ni-resist cast iron or specialised alloys

Related Case Study