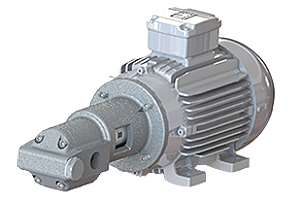

GN – Heating and Ventilation pumps

Summary:

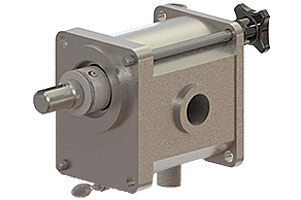

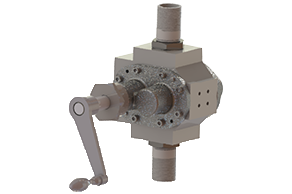

The GN range is a competitively priced cast iron gear pump available on very short lead times. This range features a close coupled design and is often foot mounted. The pump also offers additional mounting options, including flange mounted. We hold good stocks of parts and all castings are sourced locally. The GN range is also made as a Duplex pump set with a filter as one unit, often used for pumping generator fuel in buildings. This is our GD Series pump. All of our Albany Pump styles have a variety of options for the customer to specify, allowing the solution to fit the exact requirements of the application. With so many options available, no two pumps will be the same.Suited to:

The GN series is a range of robust and compact gear pumps. They provide pressures up to 10 bar, with pre-set relief valves to protect the motor from overload. Each pump is individually tested, and offers availability to work in normal, extreme or hazardous conditions. Many GN gear pumps are used for boiler feed pumping diesel or bio diesel, with transfer duties also common. The pumps are sometimes run through an inverter to slow the pump down in the event of the fluid thickening up.Feature:

- A self-priming pump which supplies a constant, non-pulsating flow

- Suiting a range of end uses, including; damp proofing, bottle washing, packaging, processing, pressure testing, transfer and more.

- Options for a motor drive or bare drive shaft

- Availability for packed adjustable gland, lip seal or mechanical seal

- Rotational speeds between 100 rev/min and 1725 rev/min

- Thrives in a variety of conditions from normal to extreme or hazardous

Applications:

Our range of GN style pumps are very versatile, with its ability to pump:

- Fuel oils

- Animal Fats

- Coolants

- Lubricants

- Solvents

- Bitumen

- Liquid wax

- Molasses

- Cooking oil

- Glue

- Varnish

- Detergents

- Anti-freeze

- Insecticides

- Sodium hydroxide

- Paints

Technical talk:

Being such an adaptable solution for those in the General & Chemical, Food, Sugar and Lubrication, Marine and Lubrication industries, there are many technical options to specify with this GN pump. Some of which being:

- Pressure: GN pumps can produce pressures of up to 10 bar depending on the available power supply (kW) and liquid

- Flow: the flow rate, as standard, is proportional to the running speed

- Suction: this will vary depending to the shaft speed, viscosity and the vapour pressure

- Temperature: when the GN pump is running at the recommended speed, standard pumps can handle liquids of up to 85 degrees Celsius

- Rotors: fitted with spur gear rotors as standard

- Rotation: the standard rotation is clockwise, from the drive shaft end of the pump. This will be standard unless requested otherwise

- Viscosity: individually tested in oil, the viscosity will rise as the temperature falls. Note: viscous liquids will cavitate at high running speeds however this can be prevented by heating liquids to reduce viscosity pumping at low speeds, or both

- Relief valves: pre-set to protect the motor from overloading and are not suitable for use as control valves. An external relief valve can be supplied

- Sealing: lip seals are principle on all F type, packed glands on P type and nitrile mechanical seals on O type, with other options available

Related Case Study